Pallet Strap T45

Semi-automatic strapping machine model Pallet Strap T45 designed to meet the needs of strapping pallets. With easyfast® strap guide disassembly system (without tools), adjustment of the welding cooling time (COOL TIME), adjustment of the sealing blade temperature and adjustment of the length of the strap to be dispensed. Simple and practical to use.

Category:

Semi-automatic strapping machinesSemi-automatic strapping machine for pallets

The new generation semiautomatic strapping machine, mod. PALLET STRAP T45, is suitable for any pallet strapping. It works with DC motors that control each function of the machine and has an electronic strap tensioning adjustable by potentiometer placed on the control panel. Compared to a traditional strapping machine, more than 30% of mechanical parts have been eliminated. It is equipped with a folding lance to facilitate the strap insertion under the pallet and a quick and easy vertical strapping.

General characteristics of the strapping machine

The Pallet Strap T45 uses a 220 V power supply | 1 ph | 50/60 Hz and has a folding lance to facilitate the insertion of the strap under the pallet. It has a strapping speed ranging from 10 to 15 cycles per minute with a maximum adjustable tensioning force up to 45 Kg. The strapping machine is equipped with 3 wheels, 1 of which is pivoting at the rear, necessary to facilitate the maneuverability of the machine. There is also: an easyfast® strap guide disassembly system, welding cooling time adjustment (COOL TIME), welding blade temperature adjustment, strap length adjustment to be dispensed.

- Power supply 220 Volts

- Power supply frequency 50/60 Hz

- Installed power 0,25 kw

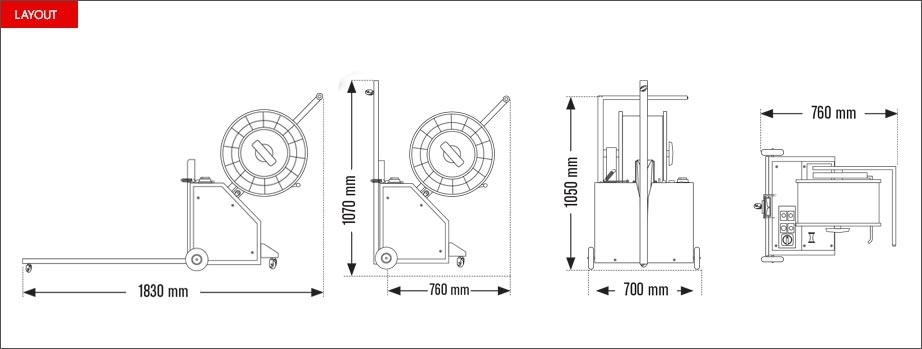

- Machine dimensions L 760 x W 700 x H 1050 mm

- Strapping speed 10/15 cycles/min

- Tension strength 3 – 45 Kg (adjustable)

- Reel internal diameter 200 mm

- Coil outer diameter 400 – 500 mm

- Coil width 190 mm

- Strap width 9 -12 – 15 mm

- Strap thickness 0,6 – 0,8 mm

- Strap type PP (polypropylene)