Easy Strap 309R – 312R

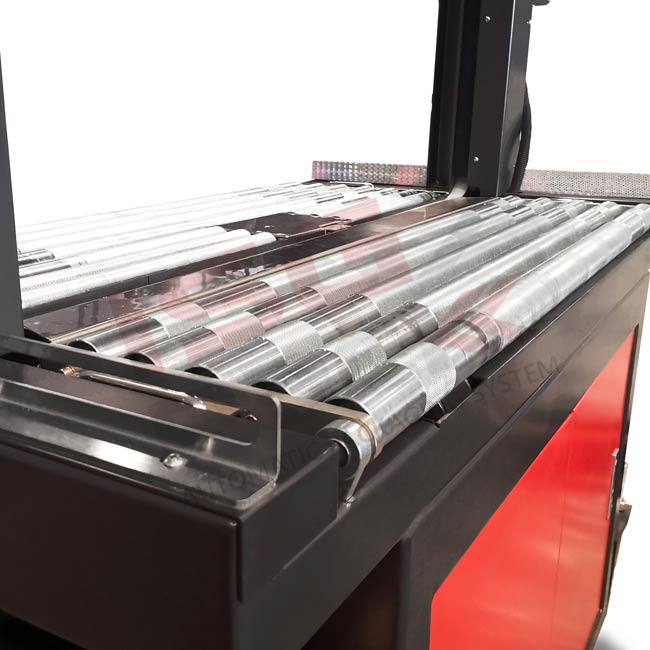

Automatic strapping machine with motorized steel roller conveyor. Thanks to its configurations it is possible to insert it in fully automated production lines. It works with direct current motors arranged for each function of the machine. Possibility to carry out multiple, double or single strapping through a photocell reader. Uses 9 or 12 mm PP strap. Robust and compact, designed for general use and medium-high work volumes. Through the control panel it is also possible to configure it in transit mode without strapping the products.

Category:

Automatic line strapping machinesAutomatic strapping machine with motorized steel roller conveyor

The fully automatic strapping machine, Easy Strap R series, is a compact, reliable, robust, and easy to use machine. It can be inserted in fully automatic production line, ensuring medium-high working capacity. The working table is equipped with motorized roller conveyor and machine can automatically work with 1-2 or multiple strappings through photocells system. There is a 180 ° rotating control panel to work on both sides of the machine. It works with DC motors that control each function of the machine. Compared to a traditional strapping machine, more than 30% of mechanical components have been eliminated. Available also with pneumatic top press and in SUS 304 stainless steel version.

- Power supply 220 Volts

- Power supply frequency 50/60 Hz

- Installed power 1 Kw

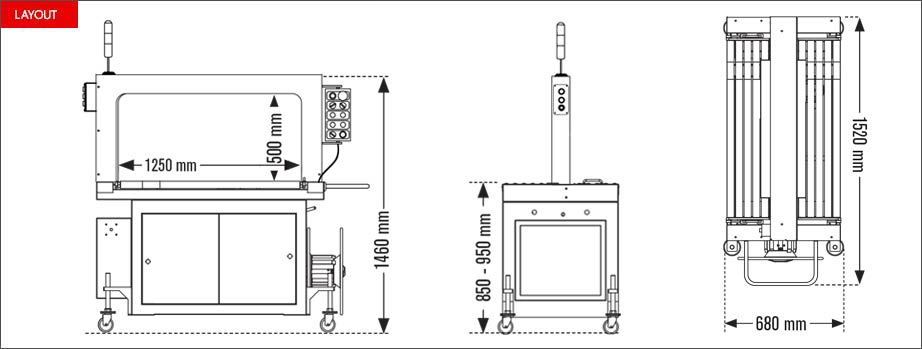

- Machine dimensions L 1520 x W 680 x H 1460 mm.

- Dimension strapping arch size L 1050 x H 1000 mm., L 1050 x H 800 mm, L 1050 x H 800 mm., L 1250 x H 1000 mm., L 1250 x H 800 mm., L 1650 x H 600 mm., L 650 x H 500 mm, L 850 x H 500 mm., L 850 x H 600 mm., L 850 x H 800 mm

- Strapping speed 45 cycles/min.

- Tension strength 0 – 45 Kg

- Type Motorized rollers

- Control panel Analog control panel

- Max product weight 30 kg

- Reel internal diameter 200 mm

- Coil outer diameter 400 – 450 mm

- Strap width 9 – 12 mm

- Strap thickness 0,45 – 0,65 mm

- Strap type PP (polypropylene)